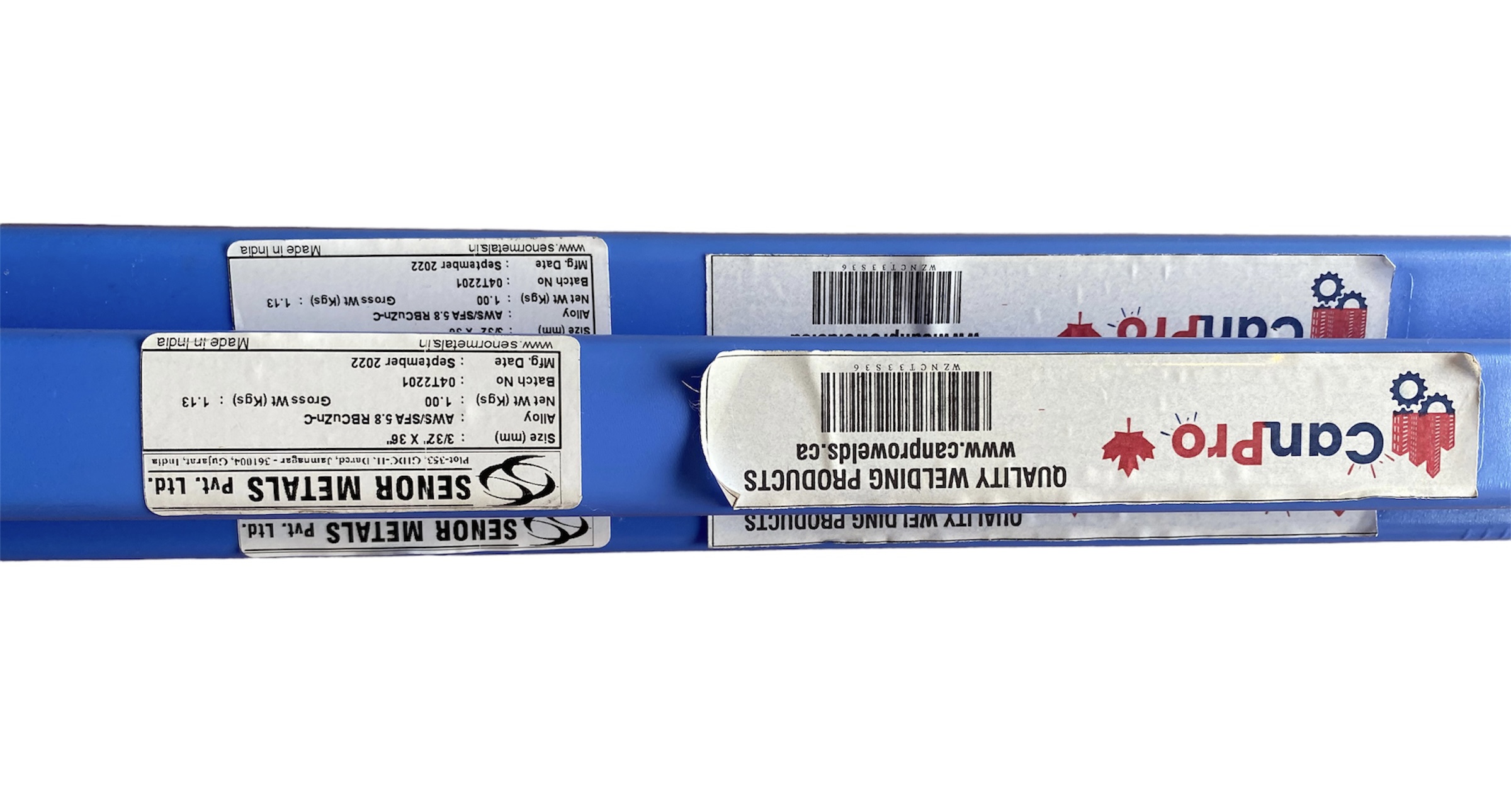

ER- RBCUZN-C 3/32 X 36 – 2.4 mm

$16.36 /lb

RBCuZn-C is a welding filler metal alloy primarily used for welding copper and copper alloys. The specifications for RBCuZn-C 3/32″ x 36″ are:

Diameter: 3/32 inch (2.4 mm)

Length: 36 inches (914.4 mm)

AWS Classification: RBCuZn-C

LFB (bare low fuming bronze) is a general purpose oxyacetylene/brazing rod used for joining various ferrous and non-ferrous metals such as carbon steel, copper alloys, cast iron, malleable iron, stainless steel and some nickel alloys. Mechanical and physical characteristics include ductility, machineability, high strength, free flowing with good tinning action and a low melting point (1630°F)

A “must have” filler metal for every machine shop, LFB is excellent for building up wearing surfaces or large areas where successive layers must be added; galvanized parts can be brazed without damaging the zinc coating. Precise balance of copper and zinc along with alloying elements of tin, iron, manganese and silicon produces weld deposits that can be easily machined but work harden once put into service; high silicon level promotes low fuming.

Some of the properties of RBCuZn-C alloy include:

- High strength: RBCuZn-C has high tensile strength, which is important for structural applications.

- Corrosion resistance: The alloy has good corrosion resistance, making it suitable for use in marine and other corrosive environments.

- Good electrical conductivity: RBCuZn-C has good electrical conductivity, which makes it a suitable choice for electrical applications.

- Good thermal conductivity: The alloy has good thermal conductivity, making it useful for heat transfer applications.

- Low melting point: RBCuZn-C has a relatively low melting point compared to other copper welding alloys, making it easier to work with.

- Good fluidity: The alloy has good fluidity, which means that it flows easily and smoothly, resulting in a uniform and consistent weld bead.

General Inquiries

There are no inquiries yet.

Reviews

There are no reviews yet.